Our Products

Utilized in the removal of plastic blow-molded parts from the molding machine. Our PTO can be customized to fit nearly any clamp-style blow molder.

Our Bottom Blow Stands stretch plastic parison within the blow molding machine and blow air from under the mold head, resulting in increased molding capabilities.

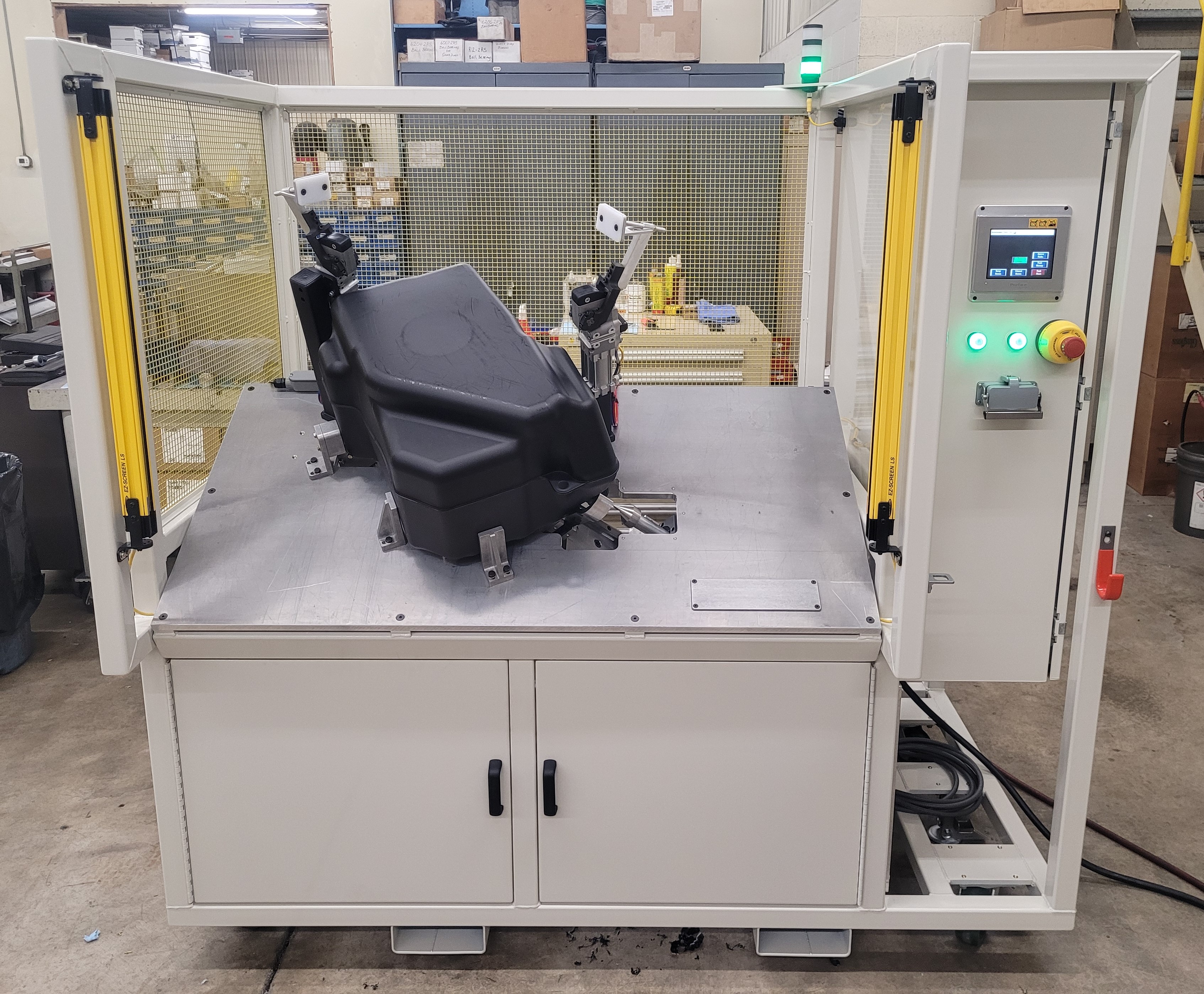

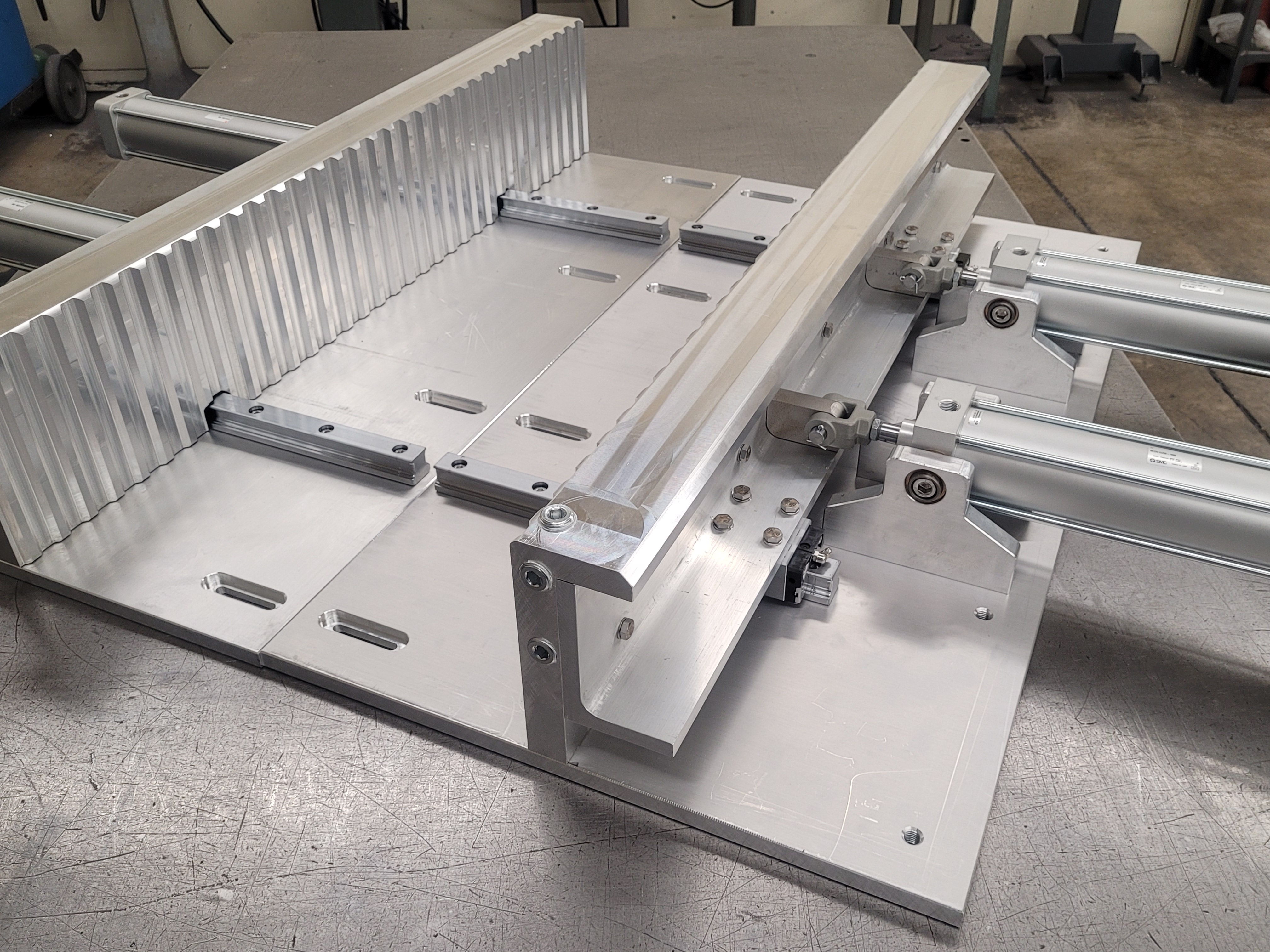

Custom built for your specific needs, our Secondary Machines perform operations such as part trimming, assembly, leak testing, plastic drilling, and plastic welding, among others.

Mounted directly above the blow mold clamps or to the blow molder framework, these products pinch the top end of the parison. Optional chilled water circulation provides a pre-hardened plastic flashing for the Part-Take-Out unit to pinch.

When changing out blow molder head tooling, HBE Machine’s Head Tooling Changers greatly simplify and make easier the process. Our Head Tooling Changers feature a powered universal adapter plate with multi-axis adjustment to unscrew nearly any head tooling.

HBE Machine is a full-service machine shop capable of complex machining. We do contract and one-off work for a variety of customers in the performance diesel industry, construction fields, and packaging industry. Contact us today to see how we can help you with your machining needs.